How to extend the life of reel mowers

The art of grinding

Milati Grass Machines caters to a wide range of professionals, including sports field managers, field managers, greenkeepers and landscapers. Its versatile product line includes various line paints and lime trucks, as well as Foley Company products such as grinding benches and other greenkeeping tools.

Arjen Spek, manager of Milati Grass: "What is often forgotten, or at least not done very well, is the maintenance of the reel mower, and more specifically the blades. With a reel mower you have two important parts: the cutting cylinder and the lower blade. These form the principle of scissors, and thus cut the grass. But, of course, it is much more than that. There are two important terms to remember, and those are 'quality of cut' and 'aftercut appearance.'"

Follow factory guidelines

"It's important that you maintain the cage as the factory specifies," says Arjen Spek. "And that is, of course, very brand-dependent. Because you want the cutting pattern and quality of cut to stay exactly as the engineer of the brand in question envisioned. In the vernacular, everyone talks about 'sharpening the reels.' To do this, the cutting cylinder is sharpened at the front of the blade. And with the lower blade just the same.

Ready? No!

"Because a cutting cylinder becomes conical in shape after a while. That's because the blade of the cutting cylinder runs in a kind of helix. Not flat, in other words. As a result, one side of the blade wears out faster than the other."

The Pi tape method

Arjen Spek: "That of course has consequences for the grinding process. Because when you grind that cylinder 'round,' you actually have to try to get that cone shape (conicity) out of it. There are various possibilities for that. For example, you have the famous Pi tape. It gives a quick, direct reading of the average diameter, with micrometer accuracy. You do this by placing the tape around the circumference of the cutting cylinder. You place the tape first on one side and then the other side of the cylinder. That way you know where you need to grind more. Some use a caliper for that."

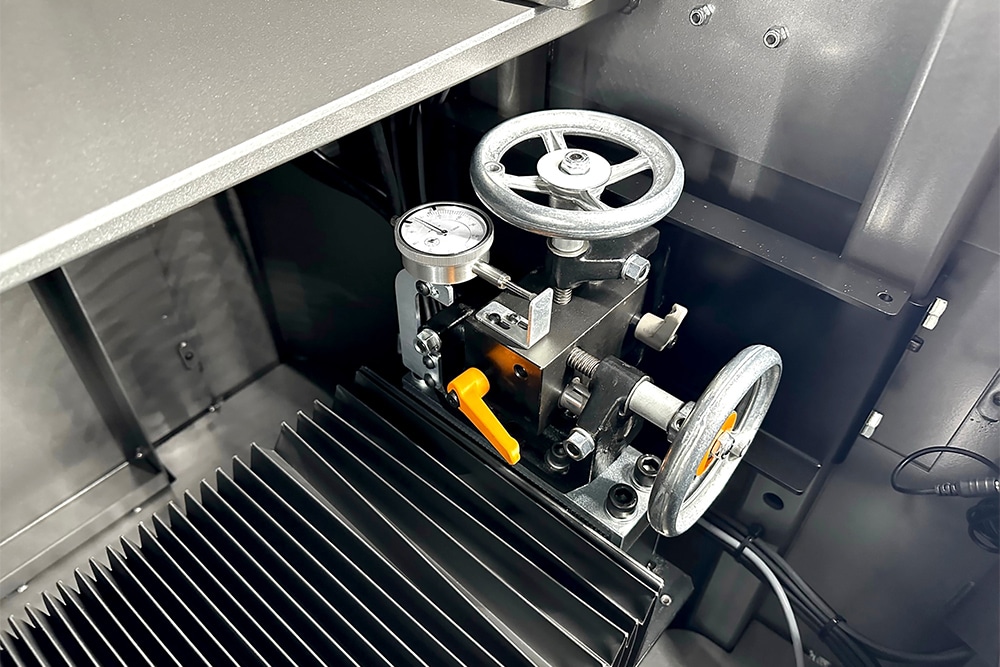

Mower maintenance with Foley grinding benches

"Of course, it could all be much easier," Spek continues. "And then the Foley grinding benches come to mind. This is the only brand worldwide that accurately measures the axis of the cutting cylinder, and ensures that that axis is parallel to the axis of the cutting stone. The machine automatically calculates where to grind off more and less, until the cutting cylinder is again completely cylindrical, rather than conical.

Because a Foley machine sharpens over the entire cylinder and not just first on one side and then on the other, which not infrequently allows the cylinder to become even more tapered. An additional advantage is that the cutting cylinder and the lower blade can do their work completely without tension, which in turn is advantageous for the overall service life of your reel mower."

"In addition to cylindrical grinding, rear grinding is also an important feature. Every mower unit, of all known brands, has a specific rear grinding angle. This can be different per brand, but with the current Foley grinding benches, this data is incorporated in the grinding bench. By grinding the cutting cylinder round, cylindrical and rear, it will be completely according to the mower brand's factory specifications."

Backlapping as a temporary grinding solution

"In between sharpening sessions, you can also choose to backlap. It's a maintenance method for keeping the blades sharp (temporarily), especially important with frequent use. Backlapping involves applying paste to the mower blades. The backlapping angle creates a space that holds the paste. The sharpening paste is thus "forced" between the cutting cylinder and the bottom blade, sharpening both components. It is not a practical alternative to sharpening, but it more or less preserves the sharpness of the blades. Compare it to sharpening a scythe with a whetstone."

'Front face' maintenance cutting edge lower blade

"Between sharpening sessions, you can also opt for 'front facing'. This is a maintenance method for keeping the front/cutting edge of the lower blade (temporarily) sharp. This can be performed with a special 'front facer', which is electrically or pneumatically driven. We also have a manual 'front facer', where you can easily and quickly maintain the cutting edge of the lower blade by hand. Both back flaps and front facers provide a better quality of cut and aftercut appearance in between the actual sharpening," concludes Arjen Spek.