E.L.S. Garden has solution for wear problems

Gravel mat needs stability and drainage long-term guarantee

Mud, puddles, ruts and weeds. After five to 10 years, a gravel driveway or parking lot can already look very different than when it was constructed. In many cases, both the drainage effect and the stability of the base and substructure begin to deteriorate. To avoid this, wholesaler in garden construction materials E.L.S. Garden developed the GravelLock gravel mat.

For the construction of gravel paths and surfaces, the garden contractor has several options. He can dump the gravel loose or use one of the many gravel mats or slabs available on the market today. Constant, however, seems to be the use of an anti-root cloth. This is considered an absolute requirement regardless of the installation method chosen. But is it?

The pots of this gravel mat are designed in such a way that even the gravel can behave as one closed pavement.

Drain

An anti-root cloth is placed directly under the gravel layer or gravel mat to inhibit weed growth without impeding the permeability of the whole. "However, the structure of such a cloth is so fine," explains Els Meynen of E.L.S. Garden, "that the dust and dirt that get into the gravel layer through wind and use cannot get through. After only three to four years, an anti-root cloth begins to silt up as a result." The result? Not only does rainwater find its way to the soil much more slowly - which can lead to mud and puddling in extreme cases - but an entirely new and fertile breeding ground for weeds is formed on the anti-root cloth. "So in the long run, an anti-root cloth achieves just the opposite of its original function."

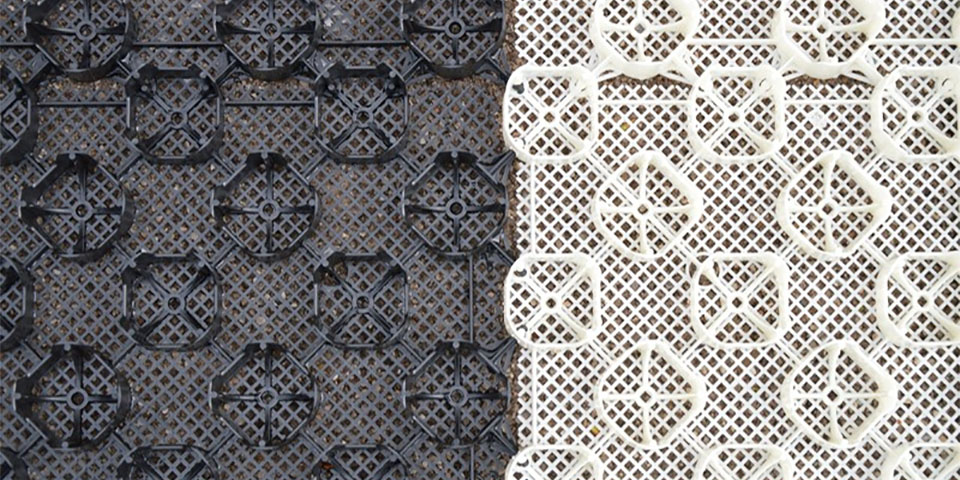

In response to this problem, E.L.S. Garden developed an alternative and 100% Belgian gravel mat: the GravelLock. This polypropylene sheet does not require an anti-root cloth, but instead is provided at the bottom with a 4 x 4 mm fine mesh grid and is placed on a base of stone rubble, possibly in combination with an equalizing gravel-sand layer. "Small organic material thus easily washes through to the bottom of the gravel mat, where worms and other soil life can digest and further drain it. The draining function of the gravel surface is thus maintained for a long time, which given the hydrological problems of recent years is very important anyway."

As an alternative to using an anti-root cloth, GravelLock has a fine mesh grid in PE at the bottom.

Stabilize

Using an anti-root cloth, by the way, can also have negative effects on the stability of a gravel path or site, according to Els Meynen. "If the cloth is not attached directly to the gravel sheets used, then it is possible that they will slide on it. If, on top of that, the gravel sheets are also loose from each other, then stability is even less assured."

The solution is to make the entire gravel mat function as a single unit. The basic modules of the GravelLock, each measuring 490 x 490 mm x 40 mm, are therefore equipped with pin-hole connections that allow them to be easily clicked together. This creates one large framework that locks firmly into the substructure under the influence of the weight of the gravel. "Moreover, because the pots in this gravel mat are separate from each other and have several openings at the top, the filling material remains in contact with itself over the entire surface. Once completely overfilled, therefore, the gravel will also behave as one closed pavement or mass."

The latter offers an advantage not only for the stability of the whole, Els knows, but also for maintenance. "If some weeds do come through the gravel deck here and there, they can easily be pulled out, just like in a regular gravel pavement."

The modules of the GravelLock gravel mat are easily clicked together for one sturdy and stable unit.

Simple construction

The GravelLock gravel mat is suitable for all regular applications with the exception of heavy industrial traffic with non-maintaining tandem axles. Thanks to the flexibility of the material, even slightly sloping terrains can be realized. To shape the slab to suit the project, simply snap together several basic modules and trim where necessary with a grinding wheel.

Fill materials between 5 and 25 mm provide the best results, and a usage quantity of about 1 m3 of gravel per 20 m2 or a thickness of 50 to 60 mm is expected. If one wants to speed up the compacting and setting of the gravel mass and sub-base, it is possible to compact the whole immediately after construction.